Zmogljivi in cenovno ugodni 3D tiskalniki za profesionalce

Formlabs vzpostavlja industrijsko merilo profesionalnega 3D tiskanja za podjetja po vsem svetu z dostopnimi, zanesljivimi namiznimi 3D tiskalniki. Optimizirajte svoje prototipe in izdelavo s 3D natisnjenimi kosi visoke ločljivosti po nizki ceni.

Form 3

Profesionalno namizno 3D tiskanje

Z napredno tehnologijo Low Force Stereolithography (LFS) ™ je Formlabs v celoti prenovil 3D tiskanje na osnovi smol in zmanjšal sile tiskanja.

Vse to je mogoče v prostornini gradnje 14.5 × 14.5 × 18.5 cm.

Form 3L

Veliki deli, velika zmogljivost

Z veliko prostornino 33,5 × 20 × 30 cm (13,2 × 7,9 × 11,8 in) v enem opravilu lahko natisnete en velik ali več majhnih delov.

Materiali

Z navzkrižno združljivim sistemom kartuš nemoteno preklapljajte med knjižnico splošnih in specialnih smol.

Formlabs knjižnjica materialov vsebuje 25+ smol, ki se delijo v naslednje skupine: Standardne, Inženiring, Dentalne in Zdravstvene, Nakit

Standard

Inženiring

Za zdravstvo

Za zlatarje

Rešitve za naknadno obdelavo

Programska rešitev

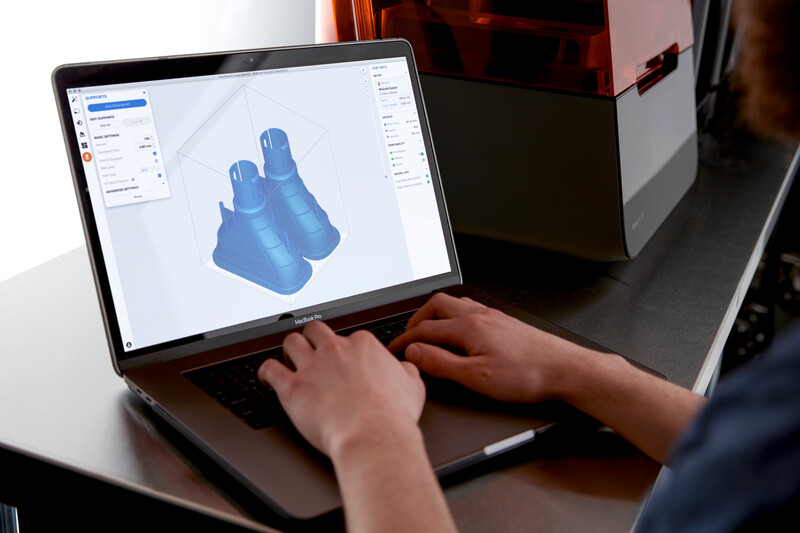

Programska oprema za 3D tiskanje – PreForm

Samodejni algoritmi PreForm nastavijo postavitev, usmeritev in podpore vašega tiska, tako da lahko vsi v ekipi uspešno tiskajo brez posebnega usposabljanja.

Strokovni uporabniki lahko ročno prilagodijo različne parametre, na primer gostoto in velikost podpor.

Oblikujte svoj model v standardni programski opremi CAD, nato datoteko STL ali OBJ uvozite v programsko opremo PreForm. Pripravite model v nekaj minutah, ga naložite v tiskalnik in pustite, da se gradi. PreForm je integriran z najbolj priljubljenimi programi CAD, in s tem olajša postopek modeliranja.

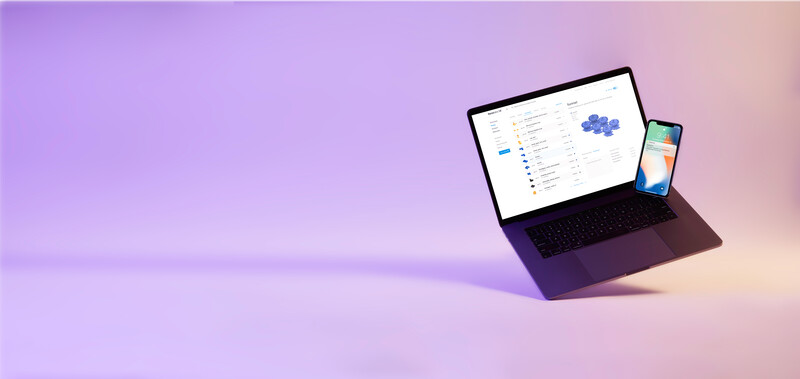

Daljinsko upravljanje preko aplikacije Dashboard

Uporabite spletno nadzorno ploščo za upravljanje tiskalnikov, materialov in skupin.

Upravljajte svoj inventar materialov in rezervoarjev za smole, in bodite vedno na tekočem, ko pride čas za menjavo potrošnega materiala.

Omogočite obvestila preko SMS in e-pošte in prejmite obvestila, končanem tisku ali če vaš tiskalnik potrebuje pozornost.

Pred odhodom pripravite tiskalnik, nato pa z oddaljenim tiskanjem začnite od koder koli.