ENGINEERING RESINS

Za funkcionalno uporabo

Posebej oblikovane inženirske smole za funkcionalno uporabo zagotavljajo oblikovalcem orodja za hitro prototipiranje delov z lastnostmi, podobnimi materialom za končno uporabo. Na voljo tudi za dele za uporabo v industriji in za ustvarjanje različnih orodij.

Od elastičnih do togih, vse do visokotemperaturnih smol.

Elastic 50A

Elastic 50A

Flexible 80A

Flexible 80A

Flame Retardant (FR)

Flame Retardant (FR)

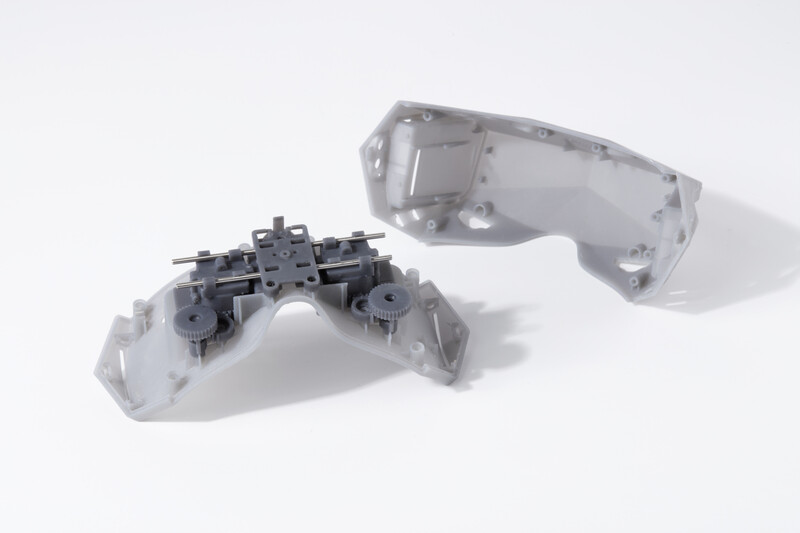

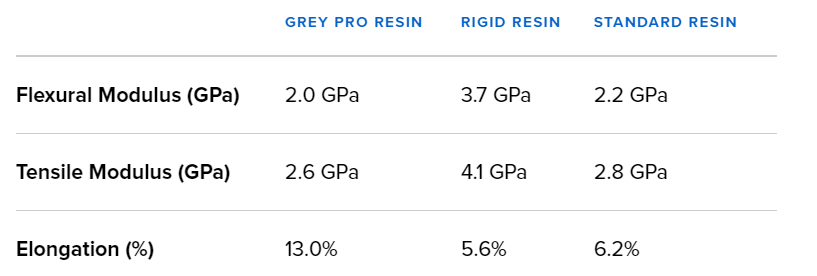

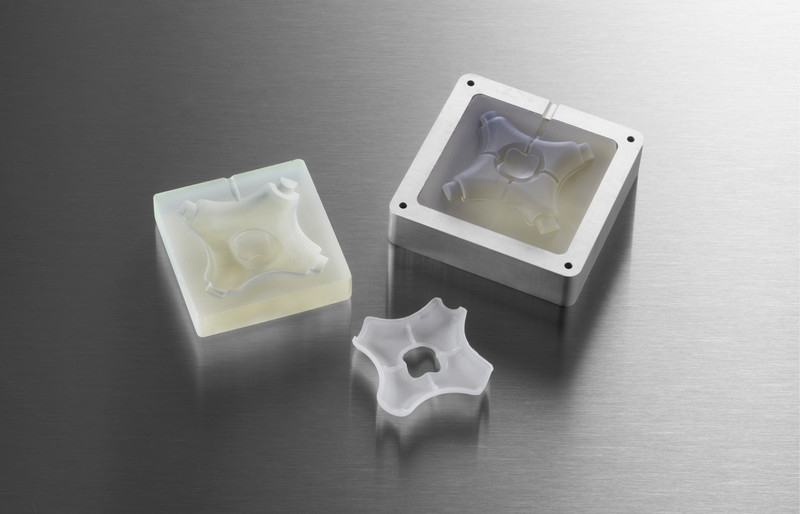

Grey Pro

Grey Pro Resin ponuja visoko natančnost, zmerno raztezanje in nizko lezenje. Ta material je odličen za konceptualno modeliranje in funkcionalno izdelavo prototipov, zlasti za dele, ki bodo večkrat obdelani.

Grey Pro Resin ponuja visoko natančnost, zmerno raztezanje in nizko lezenje. Ta material je odličen za konceptualno modeliranje in funkcionalno izdelavo prototipov, zlasti za dele, ki bodo večkrat obdelani.

Grey Pro Resin je idealna za:

- Testiranje oblike in ujema

- Injekcijski oblikovani prototipi izdelkov

- Oblikovalci kalupov za plastiko, silikone in še več

- Priprave in vpenjala za proizvodnjo

Podpira tiskanje višine sloja: 100 in 50 mikronov

Potrebno naknadno strjevanje.

Zahteva Resin Tank LT za Form 2 tiskalnik.

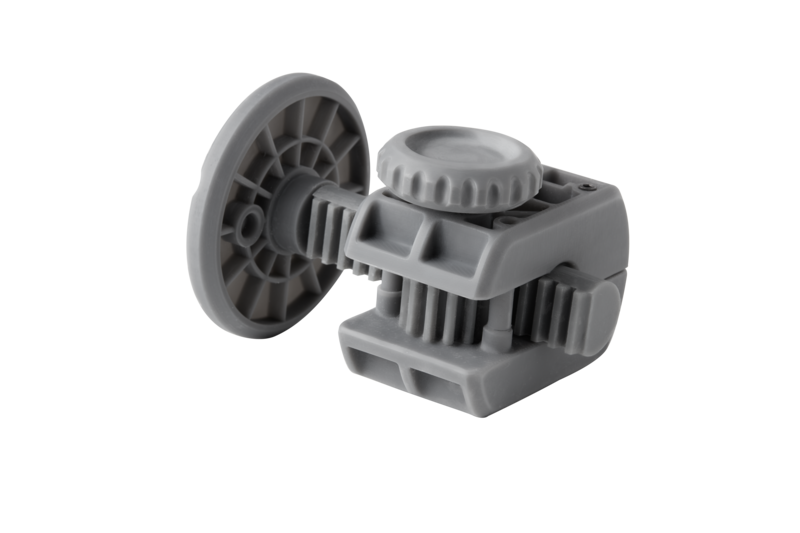

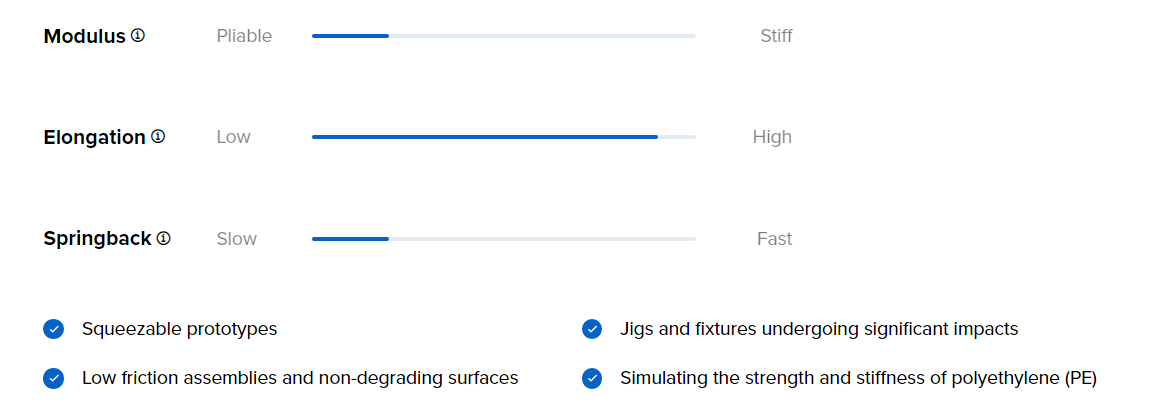

Durable

Durable Resin material je najbolj upogljiv in trpežen material v Formlabs funkcionalni družini žilavih in trpežnih smol. Izberite trajno smolo za stisljive dele in sklope z nizkim trenjem.

- Stisljivi prototipi in sklopi z nizkim trenjem

- Nosilci in priprave z visokimi udarnimi obremenitvami

- Sklopi z majhnim trenjem in nerazgradljive površine

- Simulacija trdnosti in togosti polietilena (PE)

Podpira tiskanje višine sloja: 100 in 50 mikronov

Potrebno naknadno strjevanje.

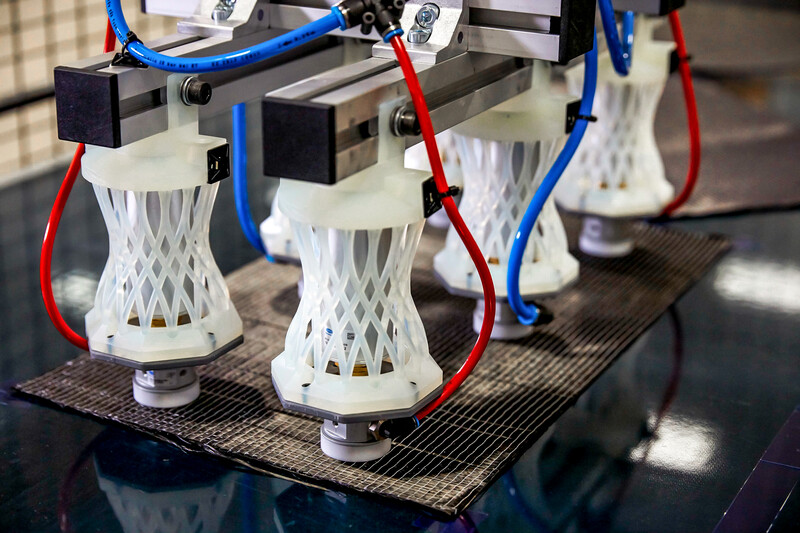

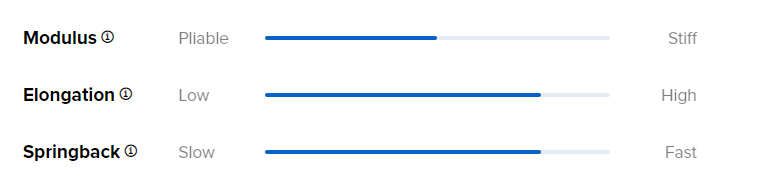

Tough 1500

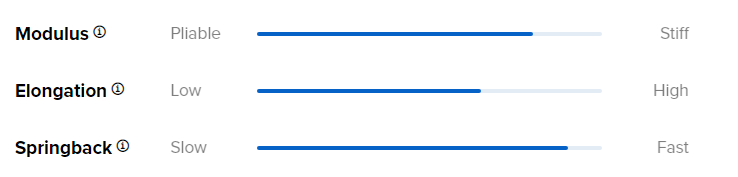

Tough 1500 Resin ustvarja trdne in upogljive dele, ki se pod cikličnimi obremenitvami hitro upognejo in vrnejo nazaj v originalno stanje. Ta material je idealen za funkcionalne prototipe, vijake in napeljave ter priključke, ki se začasno odklonijo. Prav tako simulira polipropilenske dele glede na togost in trdnost.

Tough 1500 Resin ustvarja trdne in upogljive dele, ki se pod cikličnimi obremenitvami hitro upognejo in vrnejo nazaj v originalno stanje. Ta material je idealen za funkcionalne prototipe, vijake in napeljave ter priključke, ki se začasno odklonijo. Prav tako simulira polipropilenske dele glede na togost in trdnost.

- Simulacija trdnosti in togosti polipropilena (PP)

- Prototipi in konektorji, kot so vzmeti, zaskočni nastavki, stiskalni nastavki in tečaji

- Poliran skoraj do optične prosojnosti, zaradi česar je idealen za ustvarjanje prosojnih modelov, ki prikazujejo notranjo anatomijo, ali za izdelavo prototipov delov, običajno izdelanih iz polikarbonata.

Podpira tiskanje višine sloja: 100 in 50 mikronov

Potrebno naknadno strjevanje.

Za tiskanje na Form 2 potrebujete Resin Tank LT.

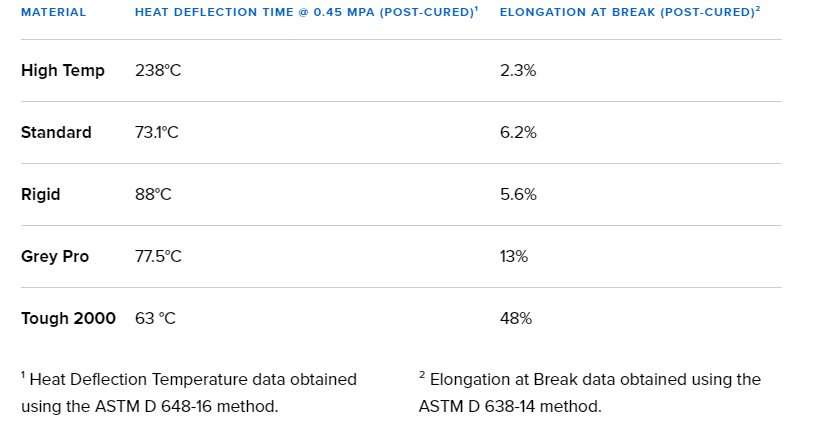

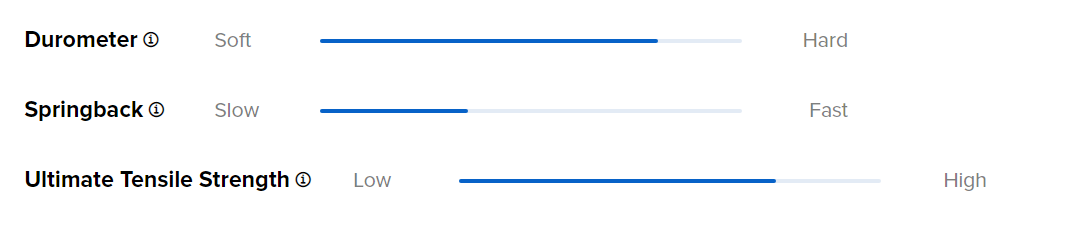

Tough 2000

Tough 2000 Resin je najmočnejši in najtrši material v Formlabs funkcionalni družini žilavih in trpežnih smol. Izberite Tough 2000 za izdelavo močnih in trdnih prototipnih delov, ki se ne smejo zlahka upogniti.

- Močni in trdi prototipi

- Funkcionalni prototipi, kjer je zahtevana visoka odpornost proti udarcem in deformaciji

- Simulacija trdnosti in togosti ABS

Podpira tiskanje višine sloja: 100 in 50 mikronov

Potrebno naknadno strjevanje.

Za tiskanje na Form 2 potrebujete Resin Tank LT.

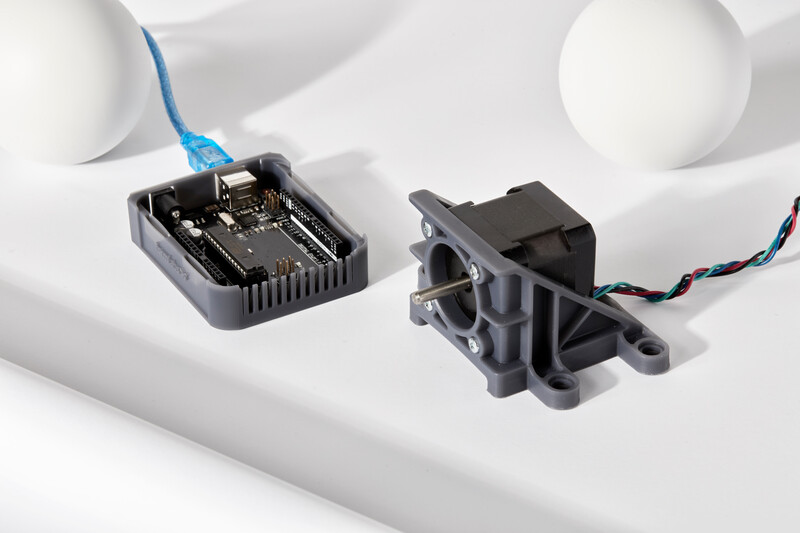

Rigid 4000

Rigid 4000 Resin je ojačana s steklom, in nudi visoko togost in poliran zaključek. Material je s časom zelo odporen na deformacije in je odličen za tiskanje tankih sten in funkcij.

- Turbine in lopatice ventilatorja

- Vrtljivi elementi, napeljave in orodja

- Kolektorji

- Električna ohišja in avtomobilska ohišja

Podpira tiskanje višine sloja: 100 in 50 mikronov

Potrebno naknadno strjevanje.

Za tiskanje na Form 2 potrebujete Resin Tank LT.

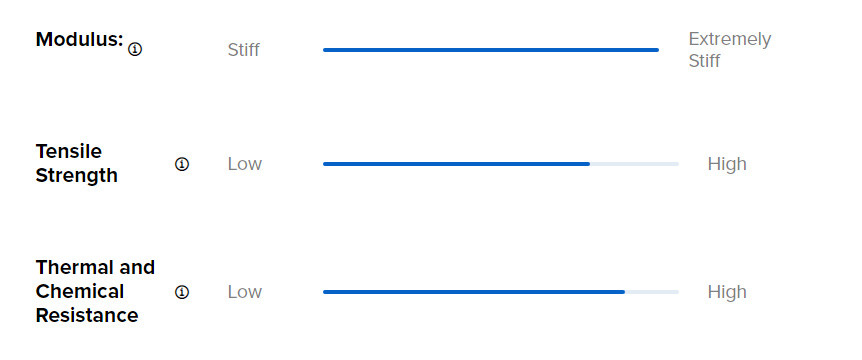

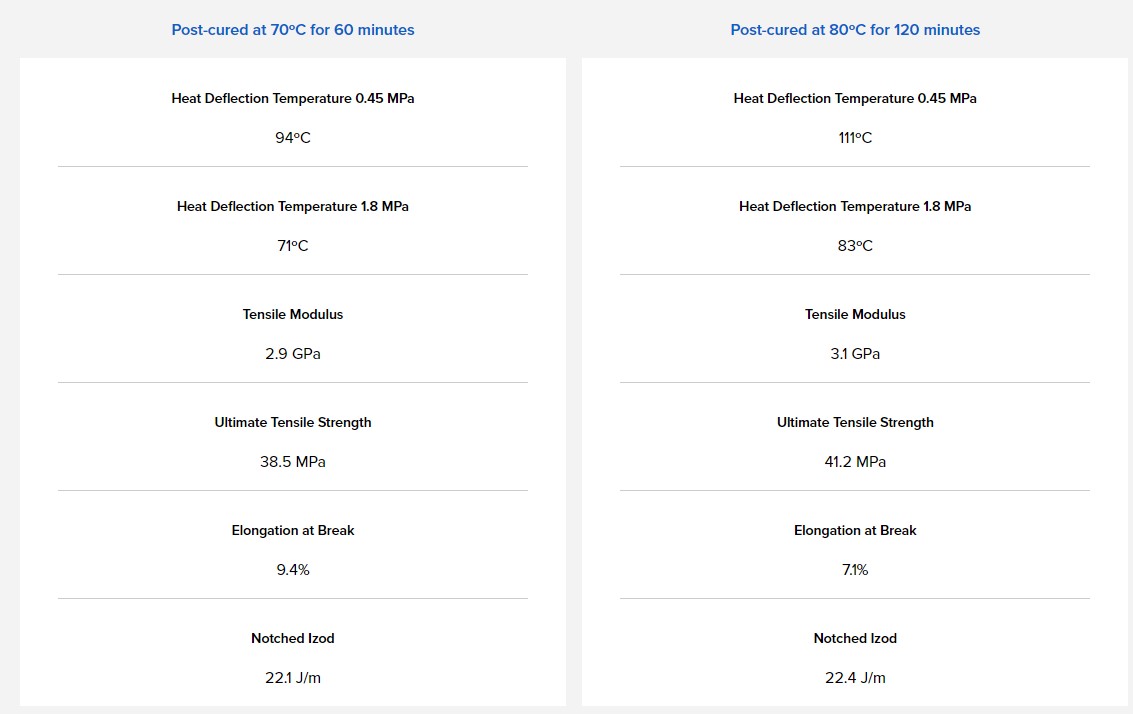

Rigid 10K

Izberite Rigid 10K smolo za natančne industrijske dele, ki morajo prenesti večje obremenitve brez upogibanja. Rigid 10K smola ima gladko mat površino in je zelo odporna na toploto in kemikalije.

"10K" v imenu predstavlja natezni modul materiala. Če potrebujete manj trden material, poskusite z Rigid 4000.

- Kratkotrajni mojstri in vložki za brizgalne kalupe

- Toplotno odporne in tekočini izpostavljene komponente, vložki in napeljave

- Aerodinamični preskusni modeli

- Simulira togost stekla in termoplastov, napolnjenih z vlakni

Podpira tiskanje višine sloja: 100 in 50 mikronov

Potrebno naknadno strjevanje.

Za tiskanje na Form 2 potrebujete Resin Tank LT.

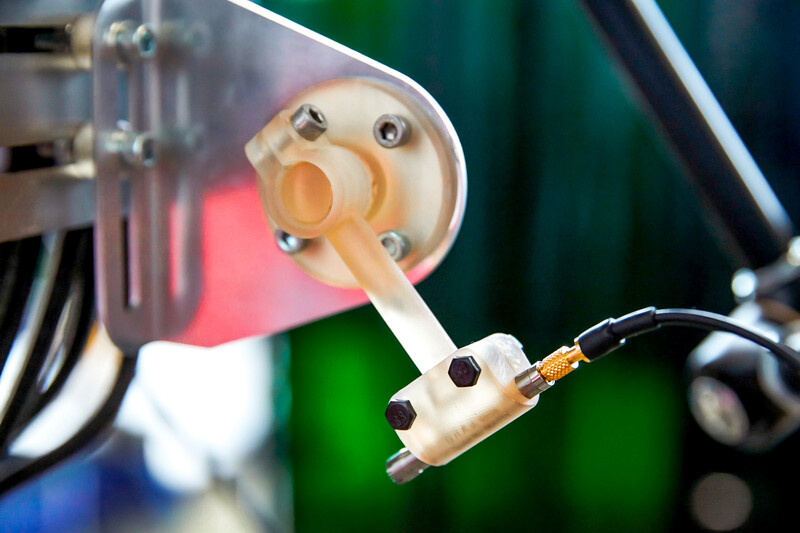

High Temp

High Temp Resin ponuja temperaturo odklona toplote (HDT) 238 ° C pri 0,45 MPa, kar je najvišja vrednost med smolami Formlabs. Uporabite ga za tiskanje podrobnih, natančnih prototipov z visoko temperaturno odpornostjo.

High Temp Resin ponuja temperaturo odklona toplote (HDT) 238 ° C pri 0,45 MPa, kar je najvišja vrednost med smolami Formlabs. Uporabite ga za tiskanje podrobnih, natančnih prototipov z visoko temperaturno odpornostjo.

- Pretok vročega zraka, plina in tekočine

- Toplotno odporni nosilci, ohišja in napeljave

- Kalupi in vložki

Podpira tiskanje višine sloja: 100, 50 and 25 mikronov

Potrebno je naknadno strjevanje z dodatno toplotno obdelavo, da se doseže največja temperatura odklona toplote 238 ° C.

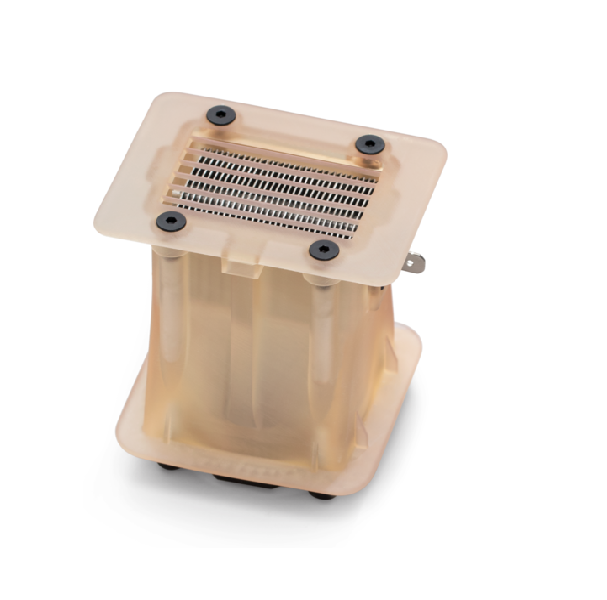

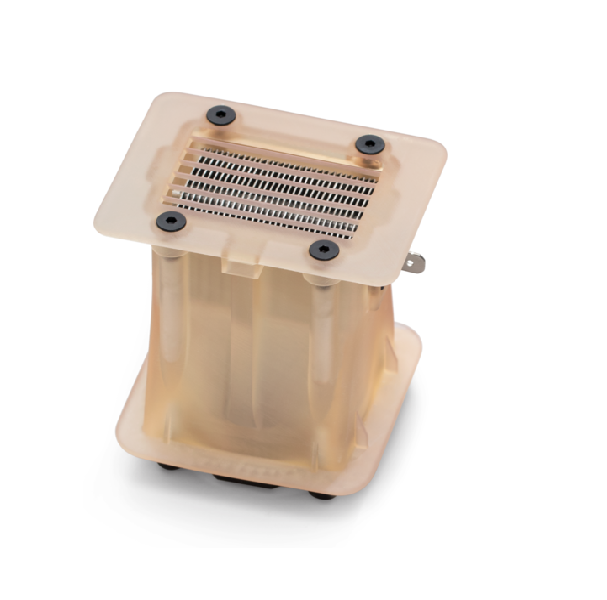

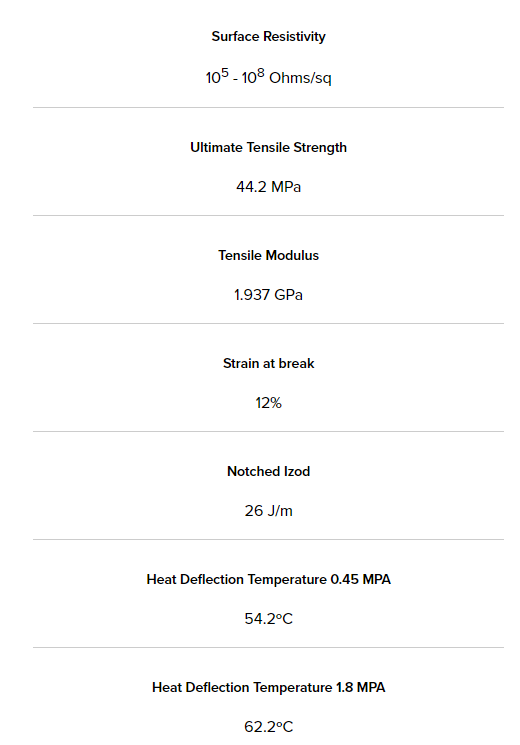

ESD

Zmanjšajte tveganje in povečajte proizvodni donos s 3D tiskanjem orodij in priprav po meri z ESD smolo. Tako zaščitite kritične komponente pred elektrostatičnim razelektrenjem. ESD smola je stroškovno učinkovita rešitev za izdelavo statično disipativnih kosov za uporabo v proizvodnji. ESD Resin is a cost-effective solution for producing static-dissipative parts designed to endure use on the factory floor.

Zmanjšajte tveganje in povečajte proizvodni donos s 3D tiskanjem orodij in priprav po meri z ESD smolo. Tako zaščitite kritične komponente pred elektrostatičnim razelektrenjem. ESD smola je stroškovno učinkovita rešitev za izdelavo statično disipativnih kosov za uporabo v proizvodnji. ESD Resin is a cost-effective solution for producing static-dissipative parts designed to endure use on the factory floor.

- Izdelavo orodij in vpetij v proizvodnji elektronike

- Anti- statične prototipe in končne komponente

- Po meri izdelane priprave za ravnanje s komponentami in njihovo shranjevanje

Podpira tiskanje višine sloja: 100 in 50 mikronov. Potrebno naknadno strjevanje.

Tiskanje možno na: Form 3, Form 3+, Form 3L, Form 3B, Form 3B+.

Kompatibilni bazeni: Form 3/3B Resin Tank V2.1, Form 3L/3BL Resin Tank V1.

Kompatibilni platformi: Form 3 Build Platform, Form 3 Build Platform 2.

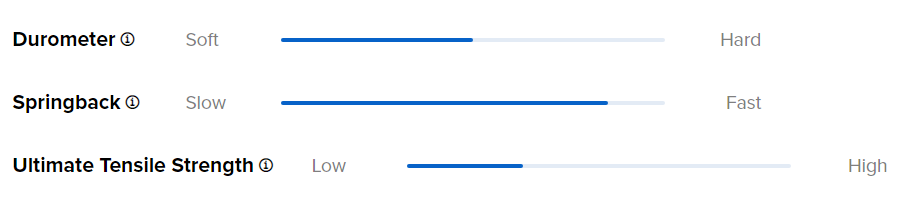

Elastic 50A

Je najmehkejša inženirska smola, ki se pojavi v knjižnici Formlabs materialov. Primerna za izdelavo prototipnih delov, ki se običajno proizvajajo iz silikona. Je elastomerični material, uporaben za dele, ki se bodo upogibali, raztezali in stiskali, ter bili zmožni iti skozi več ciklov uporabe.

- Prototipiranje nosilnih in potrošniških dobrin

- Prototipe, ki so normalno ustvarjeni s silikonom

- Robotski in ostali rekvizitni deli

- Medicinski modeli in pripomočki

Podpira tiskanje višine sloja: 100 mikronov

Potrebno naknadno strjevanje.

Za tiskanje na Form 2 potrebujete Resin Tank LT.

Flexible 80A

Flexible 80A Resin je najbolj trden material na mehak dotik v Formlabs knjižnici fleksibilnih in elastičnih smol z durometrom 80A Shore za simulacijo prožnosti gume ali TPU. Prenese upogibe, kompresije in ponovljive cikle.

- Ročaji in držaji

- Blazinjenje in blažilci udarcev

- Tesnila in maske

- Anatomija hrustanca, tetiv in ligamentov

Podpira tiskanje višine sloja: 100 in 50 mikronov

Potrebno naknadno strjevanje.

Za tiskanje na Form 2 potrebujete Resin Tank LT.

Flame Retardant (FR)

Formlabs ponosno predstavlja Flame Retardant (FR) material, samougasljiv in certificiran po standardu UL 94 V-0. Ustvarjen je bil za uporabo v transportni, letalski in medicinski industriji, pa tudi v proizvodnji in za uporabo z elektronskimi komponentami.

- Malo serijska proizvodnja delov za letalsko, avtomobilsko in medicinsko industrijo

- Orodja in pripomočki za delo v okoljih z visokimi temperaturami ali blizu virov vžiga

- Elektronska ohišja, pokrovi, ohišja konektorjev

- Elektronske aplikacije visokih moči (releji)

Podpira tiskanje višine sloja: 100 in 50 mikronov

Potrebno naknadno strjevanje.

Tiskanje možno na: Form 3, Form 3+, Form 3L, Form 3B, Form 3B+, Form 3BL.

Kompatibilne platforme: Form 3 Build Platform, Form 3 Build Platform 2, Form 3L Build Platform, Form 3L Build Platform 2.

Rezervoarji za smolo

Rezervoarji za smolo Formlabs so potrošni material, potreben za tiskanje s katerim koli 3D tiskalnikom Formlabs, ki se sčasoma obrablja glede na material, usmerjenost in položaj delov, ločljivost sloja in velikost modela.

Vsak material mora imeti svoj rezervoar za smolo, da se izognete zmanjšanju kakovosti tiska in poškodbam naprave.

Form 3 Resin Tank

3D tiskanje Low Force Stereolithography (LFS) ™ uporablja linearno osvetlitev in prilagodljiv filmski rezervoar za pretvorbo tekoče smole v brezhibne dele.

Združljivo z Form 3 in Form 3B.

Form 3L Resin Tank

3D tiskanje Low Force Stereolithography (LFS) ™ uporablja linearno osvetlitev in prilagodljiv filmski rezervoar za pretvorbo tekoče smole v brezhibne dele.

Združljivo z Form 3L in Form 3BL.

Form 2 Resin Tank

Rezervoar za smolo blokira svetlobo in je narejen iz polikarbonata, odpornega proti drobljenju. Na voljo je s pokrovom in brisalcem za večkratno uporabo, kar olajša zlaganje rezervoarjev in shranjevanje smole zunaj Form 2.

Združljivo z Form 2.

Form 2 Resin Tank LT

Ta rezervoar je bil zasnovan za tiskanje v obsežnem proizvodnem okolju in ponuja daljšo življenjsko dobo rezervoarja kot standardni rezervoar za smolo Form 2 za nekatere smole Formlabs.

Združljivo z Form 2.