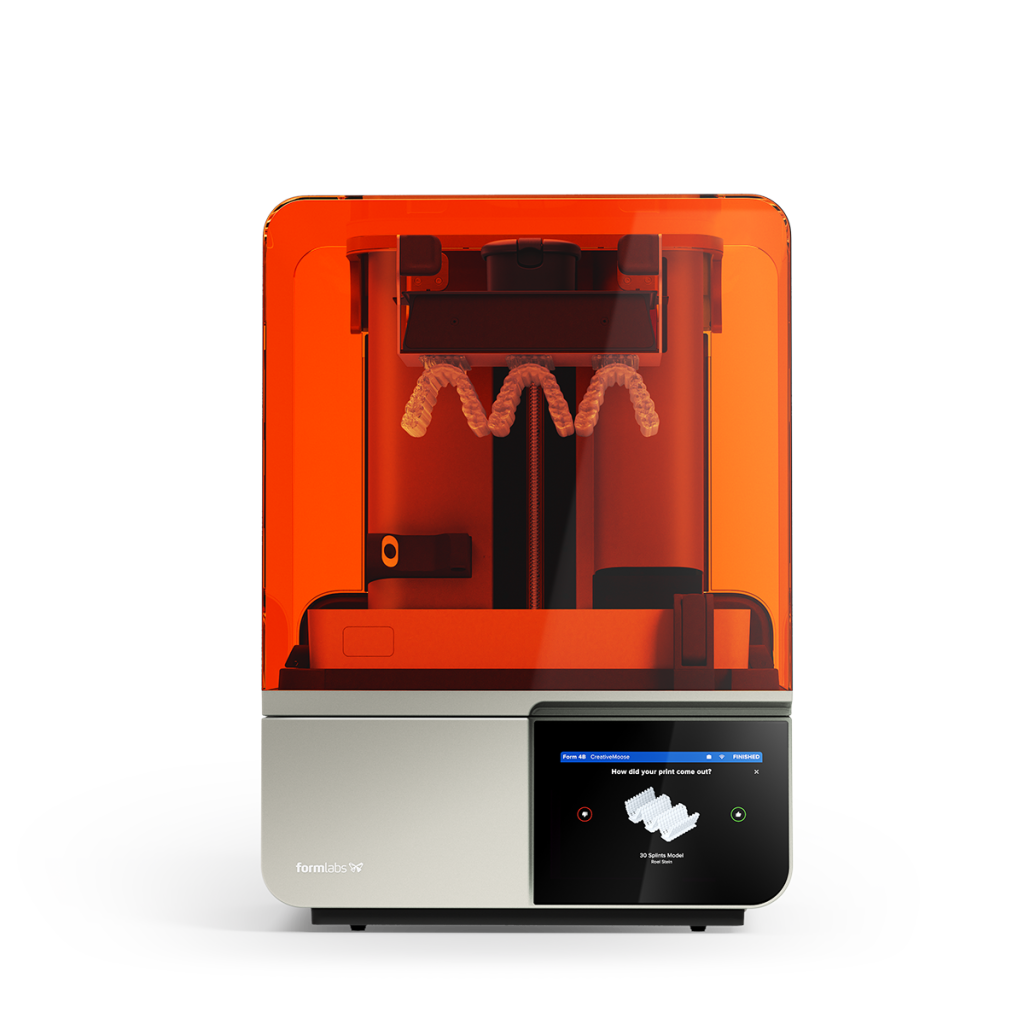

Form 4B

3D printing for healthcare

Form 4B is a blazing fast medical 3D printer that offers the most diverse materials library for healthcare. Create biocompatible, sterilizable anatomical models and medical devices fast, with easy workflows, leading reliability, versatile materials, and stunning part quality using the Form 4B ecosystem.

Blazing Speed Meets Unmatched Accuracy

Form 4B’s speed is driven by Formlabs’ new Low Force Display™ Print Engine, a powerful combination of ultra-high power LEDs, collimating lenses, optical filters, and a robust liquid crystal display.

50μm

XY Resolution

> 100 mm/h

Maximum print speed

25 – 300μm

Layer Thickness

20 × 12.5 × 21 cm

Build Volume

Low Force Display Technology

High Power Backlight Unit

The custom-designed Light Processing Unit 4 (LPU 4) inside the printer precisely masks light from the backlight unit into the shape of a printed layer.

It delivers the highest optical power on the market (13-16 milliwatts /cm²).

Minimal peel forces for maximum precision:

A proprietary, microtextured optical film that provides airflow between the flexible film resin tank and LPU, allowing for prints that rival injection molded parts.

Intelligent Control Systems:

Six onboard control systems precisely measure and maintain the temperature, resin level, print forces, and print status inside your printer.

Medical 3D Printing

The Easy Choice for Medical Appliance Production

SCAN – Collect patient anatomy digitally using an intraoral scanner. Send scans to the lab with a digital prescription or to a design station.

DESIGN – Import scan data into CAD software, where the virtual design takes place.

PRINT – Import the designed CAD files into PreForm print preparation software for print setup and send them easily to a Formlabs printer.

PREPARE – Wash, dry, and post-cure printed parts. These parts can then be used intraorally or be used to produce various indications.

Materials

High-Accuracy 3D Printing Materials for Medical Labs and Practices

Bring production in-house or improve existing workflows with industry-leading Formlabs 3D printers. Our Medical Resins empower labs and practices to rapidly manufacture biocompatible and autoclavable parts.

Accessories

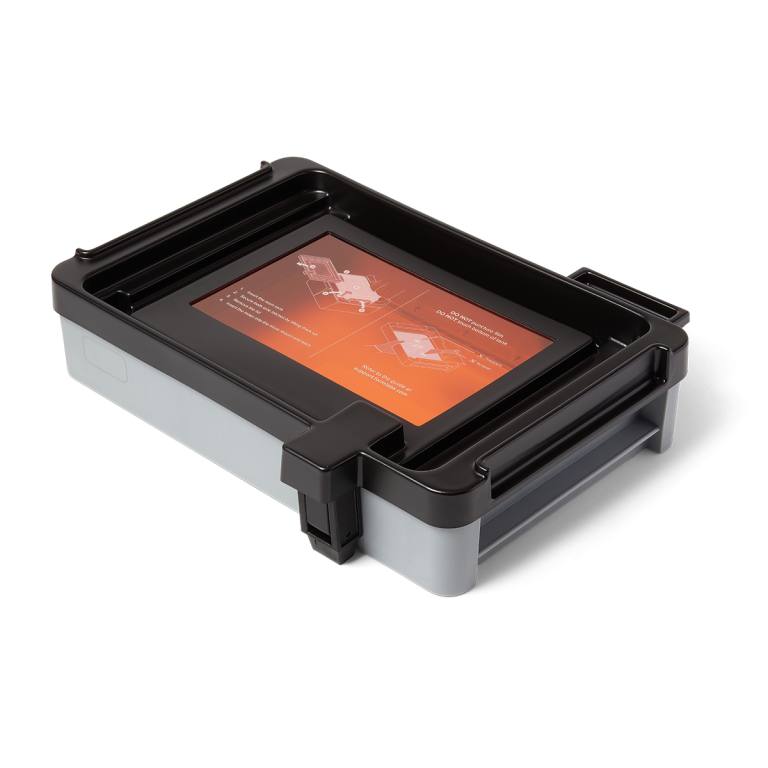

Form 4 Resin Tank

Low Force Display (LFD)™ 3D printing uses a flexible yet strong dual-layer film tank for consistent, high-quality prints. Every resin tank includes a reusable lid, making it easy to stack tanks and store resin outside of the machine. With a separate tank for each individual resin color or type, switching materials is as easy as sliding in a new tank.

Resin Tanks are built to last and deliver consistent performance for at least 75,000 layers of printing (typically 1-2 years for the average user).

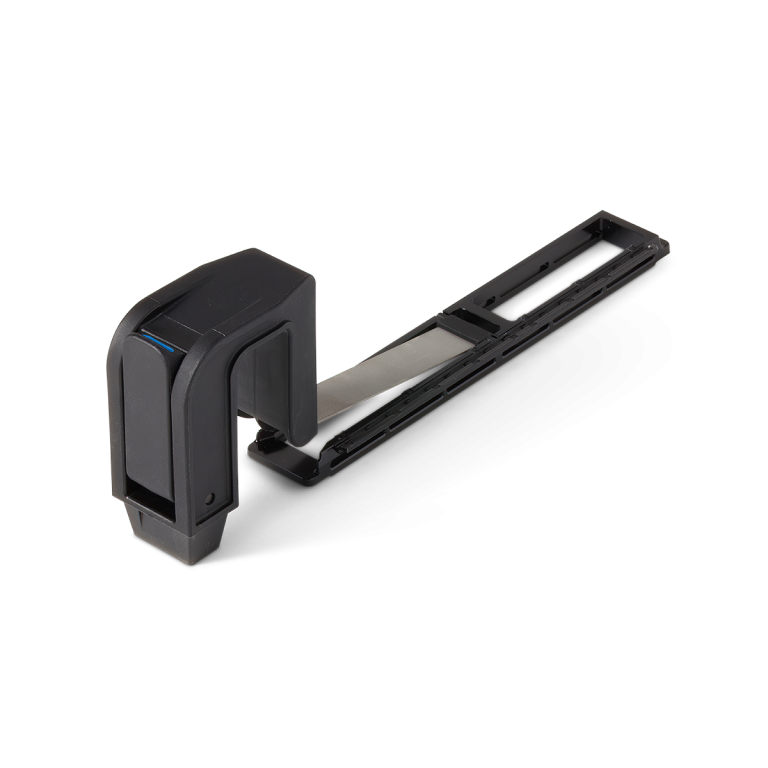

Form 4 Resin Mixer

The Form 4 Resin Mixer improves material performance by keeping resin homogenous in the tank during the printing process. A Resin Mixer is required anytime you are printing. Resin Mixers typically last for the lifetime of your printer.

For convenience, we recommend having one Resin Mixer for each Resin Tank.

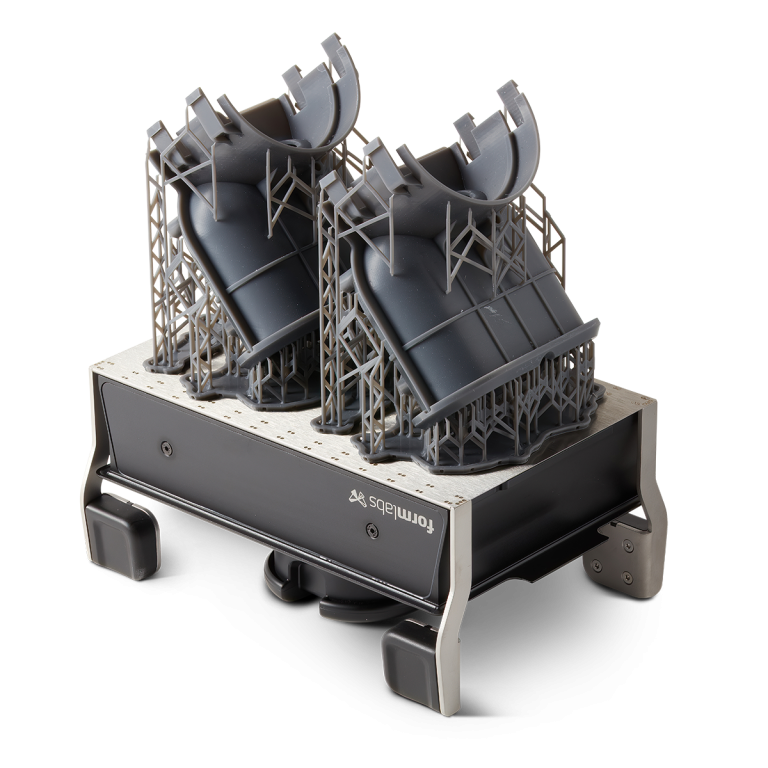

Form 4 Build Platform

Form 4 Build Platform has a durable aluminum surface. A spare Build Platform can speed up your workflow and allow for nonstop printing, whether you’re changing resins or starting a new print while you remove your part.

Build Platform Flex

Form 4 Build Platform Flex with Quick Release Technology allows you to quickly and easily remove parts from the print surface without tools in seconds. Recommended for almost all prints, Build Platform Flex eliminates the risk of damaging your part and streamlines your workflow.

Form 4 Finish Kit

Put the finishing touches on your parts quickly and easily with the comprehensive Form 4 Finish Kit, keeping your workspace clean and organized. Includes two rinse buckets, rinse basket, removal tool, plastic tank scraper, Build Platform jig, flush cutters, squeeze bottle, and disposable nitrile gloves.

Post-Processing Solution

Software Solution

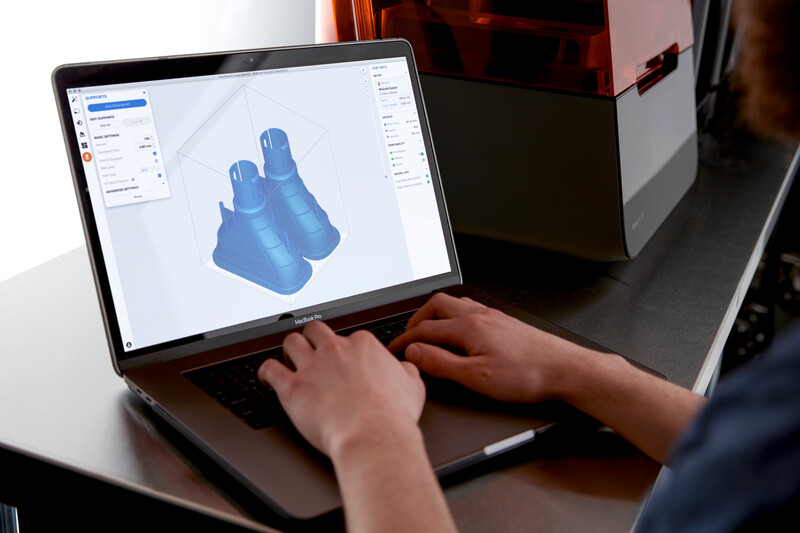

3D Printing Software – PreForm

PreForm’s automatic algorithms set up your print’s layout, orientation, and supports, so anyone on your team can print successfully without specialized training.

Expert users can manually adjust a variety of parameters, such as support density and size, to fine tune results.

Design your model in standard CAD software, then import the STL or OBJ file into our print preparation software, PreForm. Get your model ready in minutes, upload to your printer, and let it build.

Follow your actions on Dashboard

Use your online Dashboard to manage printers, materials, and teams.

Manage your inventory of materials and resin tanks so you know when it’s time to replace consumables.

Enable SMS and email notifications in Dashboard to receive notifications when prints are completed or your printer needs attention.

Prepare your printer before you leave, then start jobs from anywhere with Remote Print.