SLS MATERIALS

For functional use

3D print production-ready, end-use parts on Formlabs SLS printers with their SLS Powders. Formlabs materials, hardware, and software are developed and validated together to deliver peak performance while optimizing cost per part.

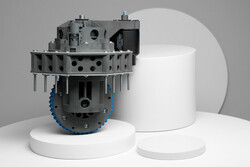

Nylon 12 GF

Nylon 12 GF

Nylon 12

Balancing strength and detail, Nylon 12 Powder is a highly capable material for both functional prototyping and end-use production of complex assemblies and durable parts with high environmental stability. Our Nylon 12 Powder is specifically developed for use on the Fuse 1.

Balancing strength and detail, Nylon 12 Powder is a highly capable material for both functional prototyping and end-use production of complex assemblies and durable parts with high environmental stability. Our Nylon 12 Powder is specifically developed for use on the Fuse 1.

Nylon 12 Powder is ideal for:

- High performance prototyping

- Small batch manufacturing

- Permanent jigs, fixtures, and tooling

- Biocompatible, sterilizable parts*

* Material properties may vary based on part design and manufacturing practices. It is the manufacturer’s responsibility to validate the suitability of the printed parts for the intended use.

Tensile strength: 50 MPa

Elongation at break (X/Y): 11%

Refresh rate: 30%

Nylon 12 GF

A glass-filled material with enhanced stiffness and thermal stability for demanding industrial environments. Choose Nylon 12 GF Powder to produce stiff functional prototypes or end-use parts for applications where structural rigidity and thermal stability are critical.

A glass-filled material with enhanced stiffness and thermal stability for demanding industrial environments. Choose Nylon 12 GF Powder to produce stiff functional prototypes or end-use parts for applications where structural rigidity and thermal stability are critical.

Nylon 12 GF Powder is ideal for:

- Robust jigs and fixtures and replacement parts

- Parts undergoing sustained loading

- Threads and sockets

- Parts subjected to elevated temperatures

Tensile modulus: 2800 MPa

Heat deflection temperature @ 1.8 Mpa: 113 °C

Refresh rate: 30-50%

Nylon 11

For highly ductile, robust parts, Nylon 11 Powder is our higher performance nylon material for functional prototyping and small batch production. Compared to Nylon 12 Powder, our Nylon 11 Powder is more flexible, less brittle, and better at printing thin walls.

For highly ductile, robust parts, Nylon 11 Powder is our higher performance nylon material for functional prototyping and small batch production. Compared to Nylon 12 Powder, our Nylon 11 Powder is more flexible, less brittle, and better at printing thin walls.

Nylon 11 Powder is ideal for:

- Impact-resistant prototypes, jigs, and fixtures

- Thin-walled ducts and enclosures

- Snaps, clips, and hinges

- Orthotics and prosthetics*

*Material properties may vary based on part design and manufacturing practices. It is the manufacturer’s responsibility to validate the suitability of the printed parts for the intended use.

Tensile strength: 49 MPa

Elongation at break (X/Y): 40%

Refresh rate: 50%

Nylon 11 CF

Get the best of nylon and carbon fiber with this highly stable, high-performance material, perfect for end-use applications that require both high stiffness and superior strength. Choose Nylon 11 CF Powder to produce lightweight rigid parts that can withstand repeated impact.

Nylon 11 CF Powder is ideal for:

- Replacement and spare alternatives for metal parts

- Tooling, jigs, fixtures

- High-impact equipment

- Functional composite prototypes

Tensile strength (X): 69 MPa

Modulus (X): 5300 MPa

Refresh rate (Inert Gas): 30%

Polypropylene

Leverage genuine polypropylene to produce works-like prototypes and durable end-use parts that are chemically resistant, weldable, and watertight. Polypropylene offers high ductility, allowing for repeated bending and flexing while ensuring durability, without the need for inert atmospheric control.

Polypropylene Powder is ideal for:

- Packaging prototypes, watertight housings, cases

- Orthotics and prosthetics

- Automotive interior components

- Strong and chemically resistant fixtures, tools, and jigs

Tensile strength : 29 MPa

Tensile modulus: 1640 MPa

Refresh rate: 50%

TPU 90A

Easily create flexible parts that withstand the demands of everyday use. TPU 90A Powder’s high elongation and superior tear strength allow you to produce functional prototypes or durable end-use parts in-house.

TPU 90A Powder is ideal for:

- Wearables and soft-touch elements

- Gaskets, seals, masks, belts, plugs, and tubes

- Protective sports equipment

- Soles, splints, orthotics, and prosthetics

- Padding, dampers, cushions, and grippers

Tear strength (X/Y): 66 kN/m

Elongation at Break (X/Y): 310%

Refresh rate: 20%