Fuse 1

Bring SLS technology to your workflow

Begin producing your own SLS complex and sturdy parts with your own Fuse 1. Reliable and easy to use.

Fuse 1

The Fuse 1 is Formlabs new 3D printer that functions on SLS technology which sinters thermoplastic and robber powder.

It provides reliability, fast and safe workflow and high throughput.

16.5 x 16.5 x 30 cm

Build Volume

Ytterbium Fiber 10W

Laser

110 μm

Layer Thickness

Affordable high part quality

Stop spending money on outsourcing for high quality SLS prints made on expensive machines.

Begin printing with affordable, reliable and user friendly Fuse 1 which rivals the quality of high cost machines.

Selective Laser Sintering Technology

No supports

Unsintered powder holeds your parts in place which provied many benefits such as no supports.

Strong parts

Strong bond of meleted powder provides strong, sturdy parts also suitable for end use.

Production

Print stack of parts in also Z direction to produce several hundred parts in little more than 20 hours!

Easy to use

Thanks to Formlabs dedication to customers the SLS technology of the Fuse one is intuitive, clean and simple to use for an affordable price.

Materials

Hassle-Free Materials Management

Choose from a wide range of advanced materials form the library which is constantly being updated with more materials.

Balancing strength and detail, Nylon 12 Powder is a highly capable material for both functional prototyping and end-use production of complex assemblies and durable parts with high environmental stability.

A glass-filled material with enhanced stiffness and thermal stability for demanding industrial environments.

For highly ductile, robust parts, Nylon 11 Powder is our higher performance nylon material for functional prototyping and small batch production.

Get the best of nylon and carbon fiber with this highly stable, high-performance material, perfect for end-use applications that require both high stiffness and superior strength. Choose Nylon 11 CF Powder to produce lightweight rigid parts that can withstand repeated impact.

Post-Processing Solution

Fuse Sift

With Fuse Sift working with SLS powder could not be more enjoyable. A closed workflow system provides clean environment and reduces particle inhalation.

Fuse sift will help you:

Prevent powder from leaving the device

Cool down your build chamber

Unpack the build chamber

Sift unsintered powder

Store fresh and used powder

Mix unsintered and fresh powder

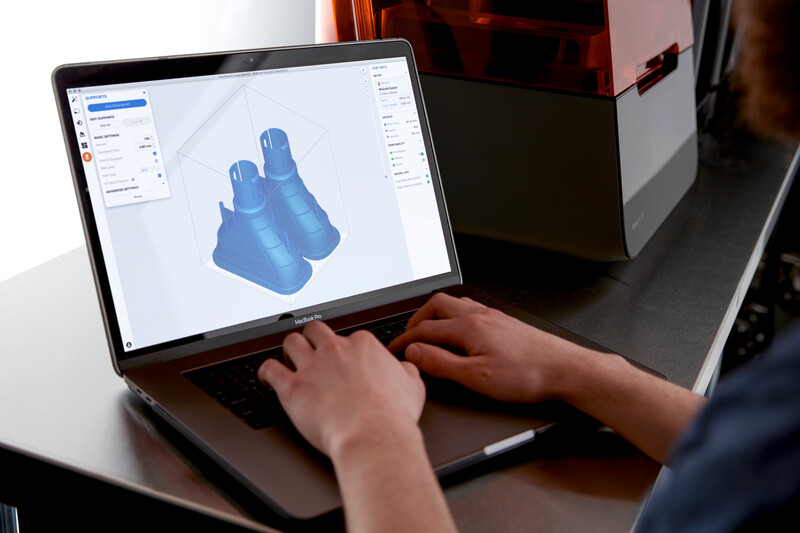

Software Solution

3D Printing Software – PreForm

PreForm’s automatic algorithms set up your print’s layout, orientation, and supports, so anyone on your team can print successfully without specialized training.

Design your model in standard CAD software, then import the STL or OBJ file into our print preparation software, PreForm. Get your model ready in minutes, upload to your printer, and let it build.

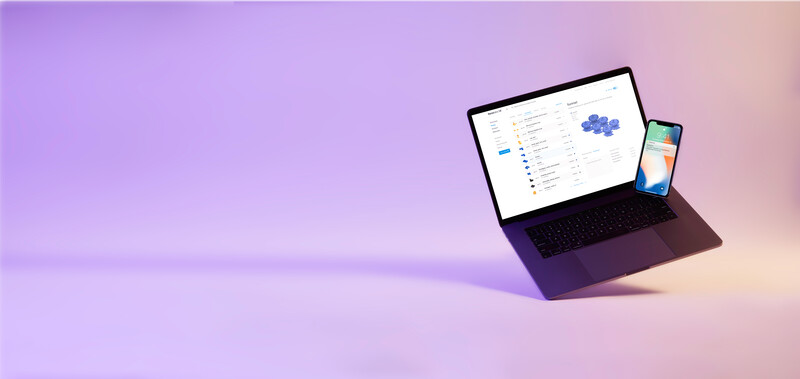

Follow your actions on Dashboard

Use your online Dashboard to manage printers, materials, and teams.

Manage your inventory of materials and resin tanks so you know when it’s time to replace consumables.

Enable SMS and email notifications in Dashboard to receive notifications when prints are completed or your printer needs attention.

Prepare your printer before you leave, then start jobs from anywhere with Remote Print.