ENGINEERING RESINS

For Functional Use

Specifically formulated Engineering resins for functional use provide designers the tools to rapidly prototype parts with properties similar to end use materials. Also available for parts to use in you industry and to create various tools.

From elastic to rigid to high temp resistance resins. Formlabs has it all.

Elastic 50A

Elastic 50A

Flexible 80A

Flexible 80A

Flame Retardant (FR)

Flame Retardant (FR)

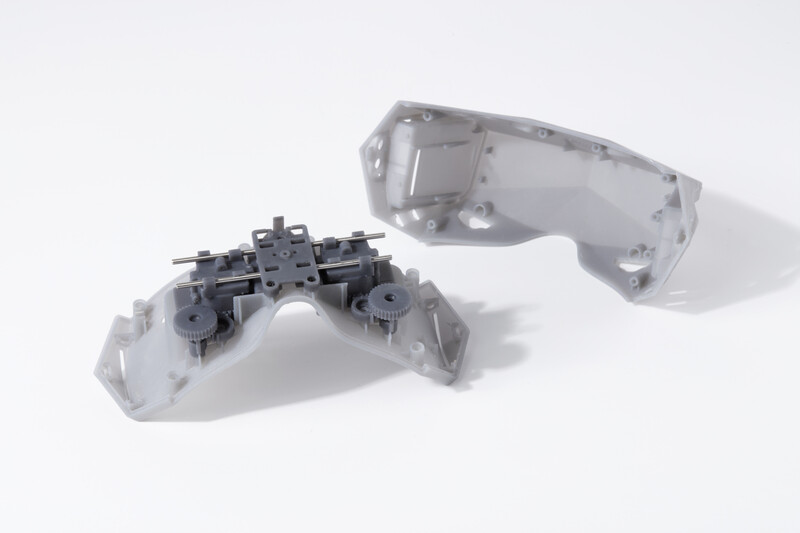

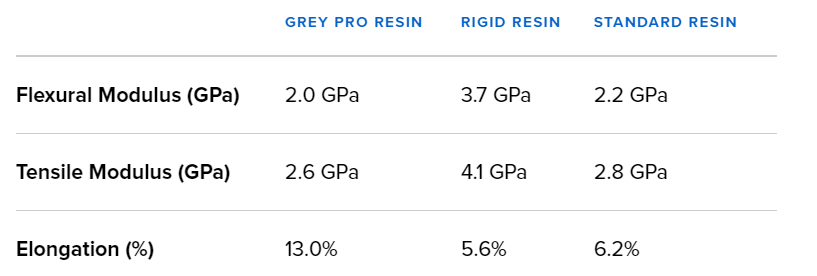

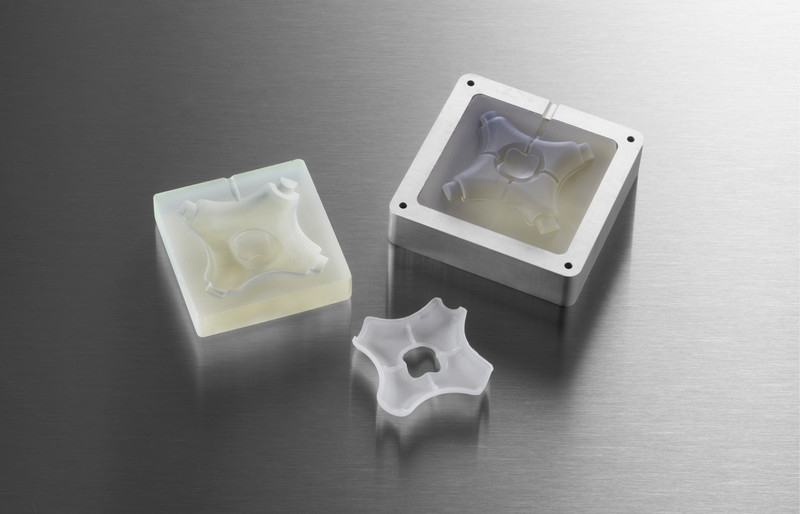

Grey Pro

Grey Pro Resin offers high precision, moderate elongation, and low creep. This material is great for concept modeling and functional prototyping, especially for parts that will be handled repeatedly.

Grey Pro Resin offers high precision, moderate elongation, and low creep. This material is great for concept modeling and functional prototyping, especially for parts that will be handled repeatedly.

Grey Pro Resin is ideal for:

- Form and fit testing

- Injection molded product prototypes

- Mold masters for plastics, silicones, and more

- Jigs and fixtures for manufacturing

Supports print resolutions: 100 and 50 microns.

Post-curing required.

Requires Resin Tank V2 for Form 3 and Resin Tank LT for Form 2.

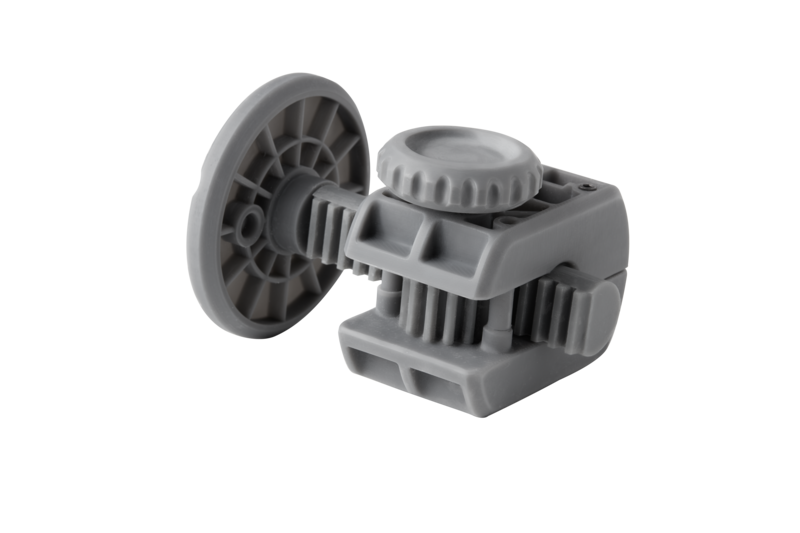

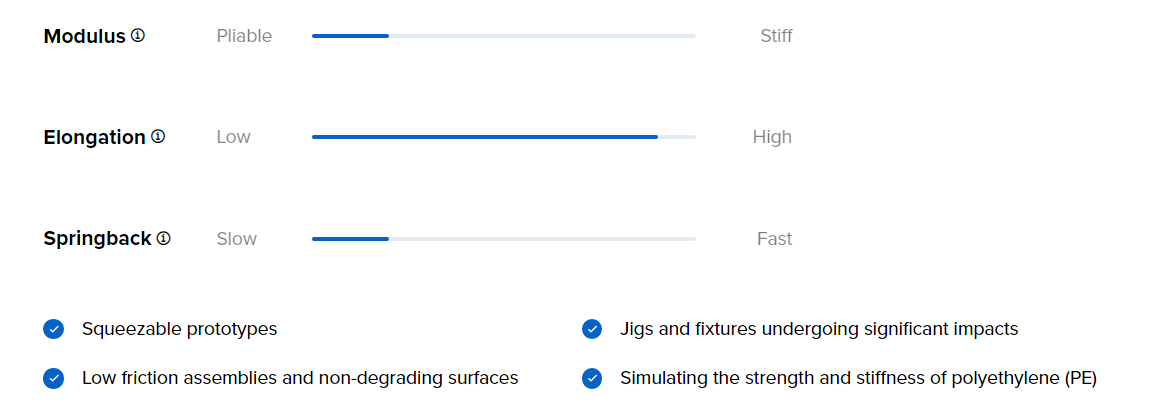

Durable

Durable Resin is the most pliable, impact resistant, and lubricious material in our functional family of Tough and Durable Resins. Choose Durable Resin for squeezable parts and low-friction assemblies.

- Squeezable prototypes and low friction assemblies

- Jigs and fixtures undergoing significant impacts

- Low friction assemblies and non-degrading surfaces

- Simulating the strength and stiffness of polyethylene (PE)

Supports print resolutions: 100 and 50 microns.

Post-curing required.

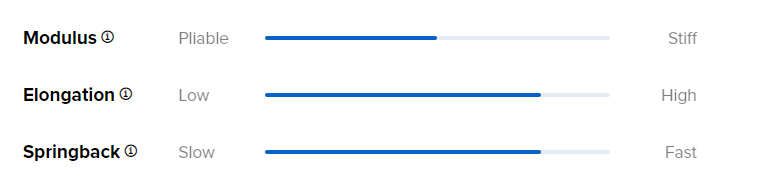

Tough 1500

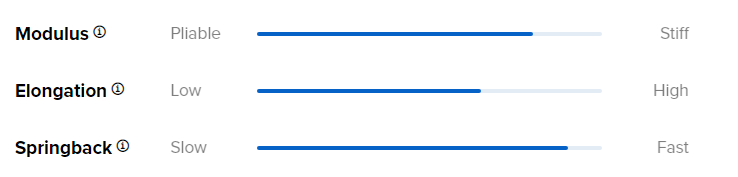

Tough 1500 Resin creates stiff and pliable parts that bend and spring back quickly under cyclic loading. This material is ideal fo functional prototyping, screws, fixtures and connections. It also simulates polypropylene pieces due to it’s rigidity and strength.

Tough 1500 Resin creates stiff and pliable parts that bend and spring back quickly under cyclic loading. This material is ideal fo functional prototyping, screws, fixtures and connections. It also simulates polypropylene pieces due to it’s rigidity and strength.

- Simulating the strength and stiffness of polypropylene (PP)

- Jigs and fixtures requiring repeated deflection

- Prototypes that repeatedly bend and quickly return to shape

Supports print resolutions: 100 and 50 microns.

Post-curing required.

Requires Resin Tank LT for printing on Form 2.

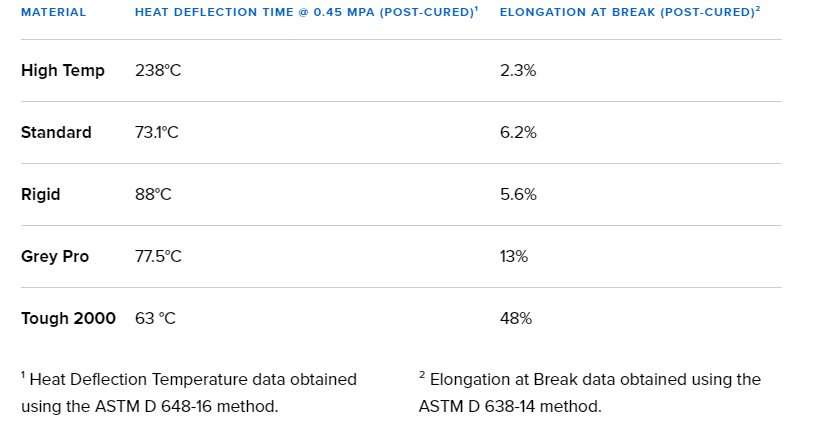

Tough 2000

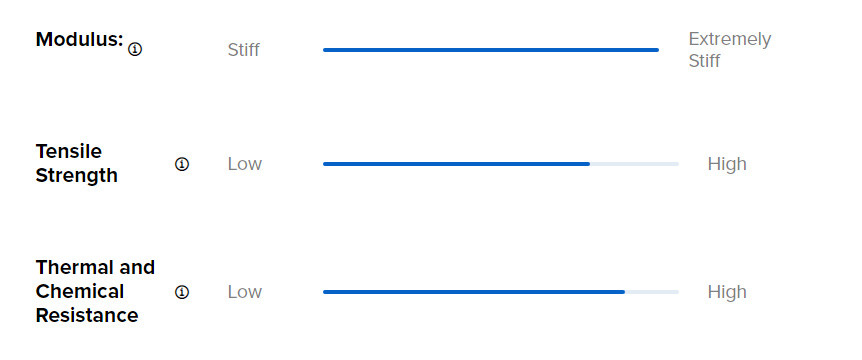

Tough 2000 Resin is the strongest and stiffest material in our functional family of Tough and Durable Resins. Choose Tough 2000 Resin for prototyping strong and sturdy parts that should not bend easily.

- Strong and stiff prototypes

- Jigs and fixtures requiring minimal deflection

- Simulating the strength and stiffness of ABS

Supports print resolutions: 100 and 50 microns.

Post-curing required.

Requires Resin Tank V2 for Form 3 and Resin Tank LT for Form 2.

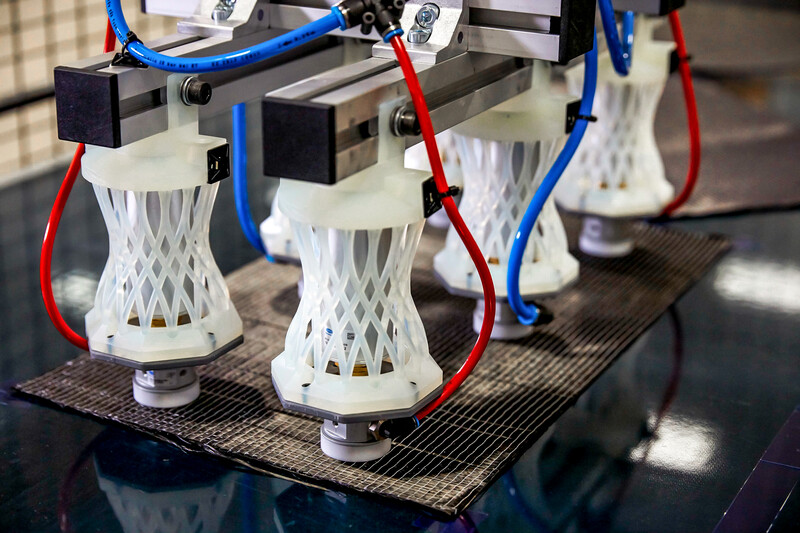

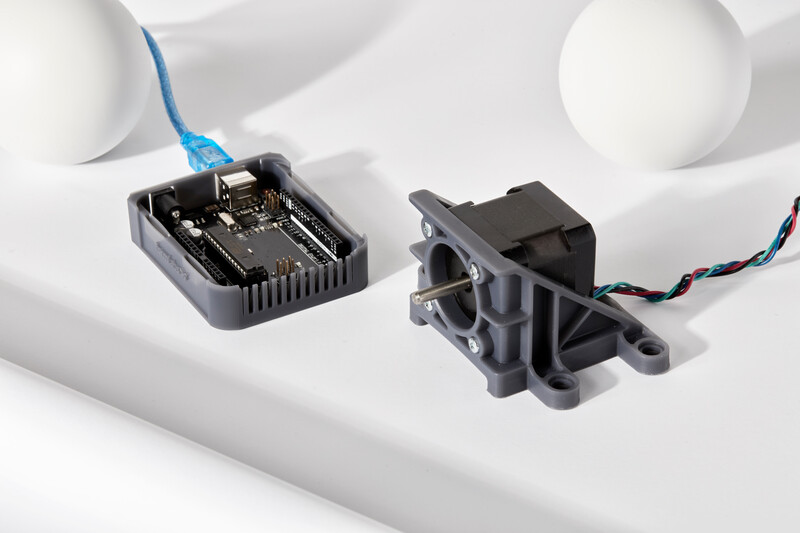

Rigid 4000

Rigid 4000 Resin is reinforced with glass to offer very high stiffness and a polished finish. This material is highly resistant to deformation over time and is great for printing thin walls and features.

- Turbines and fan blades

- Jigs, fixtures, and tooling

- Manifolds

- Electrical casings and automotive housings

Supports print resolutions: 100 and 50 microns.

Post-curing required.

Requires Resin Tank V2 for Form 3 and Resin Tank LT for Form 2.

Rigid 10K

Choose Rigid 10K Resin for precise industrial parts that need to withstand significant load without bending. Rigid 10K Resin exhibits a smooth matte finish and is highly resistant to heat and chemicals.

The “10K” in the name represents the material’s tensile modulus. If you need a less stiff material, try Rigid 4000.

- Short-run injection mold masters and inserts

- Heat resistant and fluid exposed components, jigs, and fixtures

- Aerodynamic test models

- Simulates stiffness of glass and fiber-filled thermoplastics

Supports print resolutions: 100 and 50 microns.

Post-curing required.

Requires Resin Tank V2 for Form 3 and Resin Tank LT for Form 2.

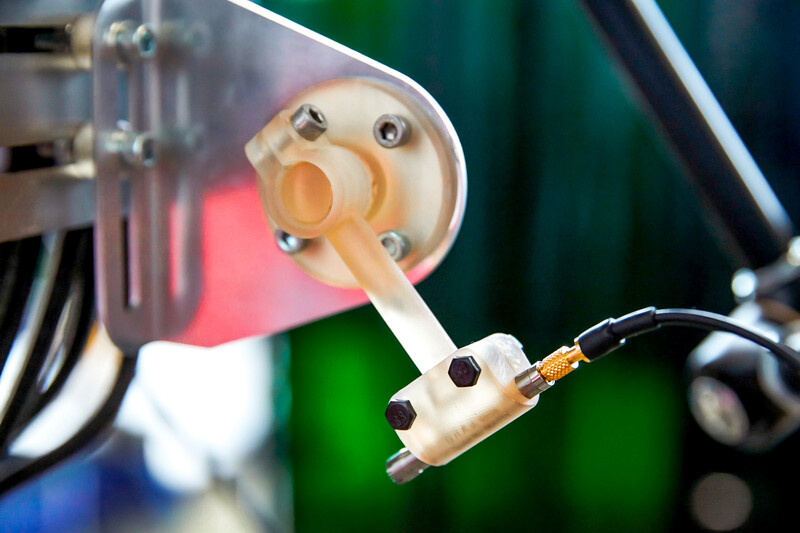

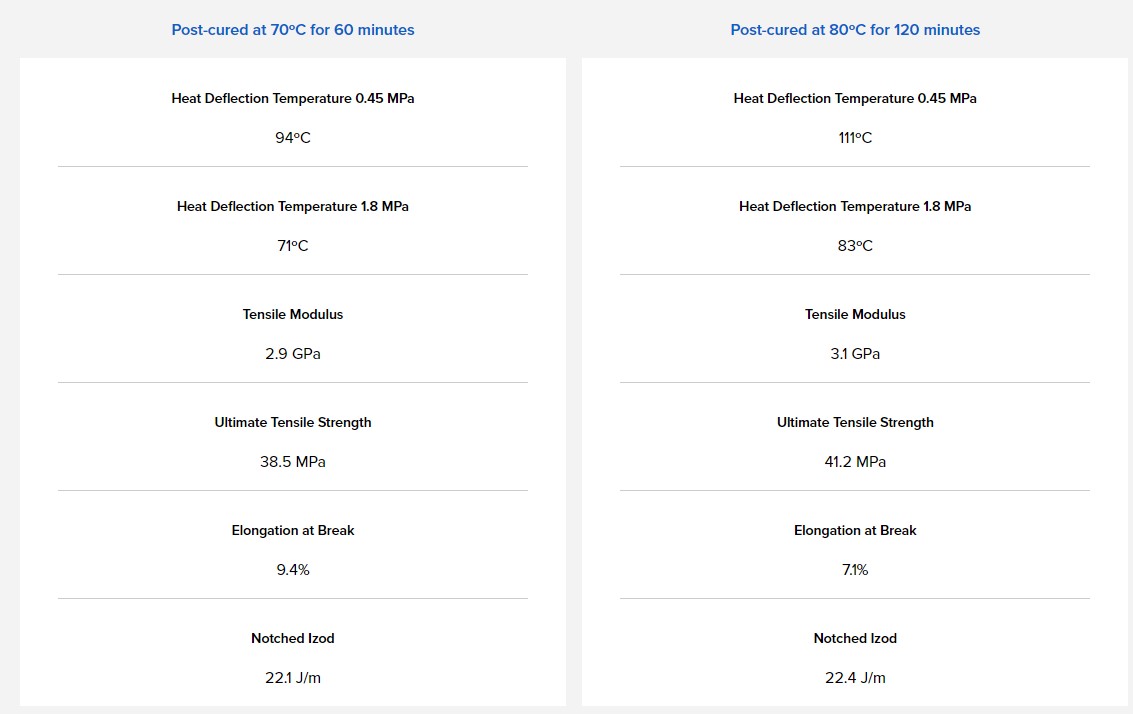

High Temp

High Temp Resin offers a heat deflection temperature (HDT) of 238 °C @ 0.45 MPa, the highest among Formlabs resins. Use it to print detailed, precise prototypes with high temperature resistance.

High Temp Resin offers a heat deflection temperature (HDT) of 238 °C @ 0.45 MPa, the highest among Formlabs resins. Use it to print detailed, precise prototypes with high temperature resistance.

- Hot air, gas, and fluid flow

- Heat resistant mounts, housings, and fixtures

- Molds and inserts

Supports print resolutions: 100, 50 and 25 microns.

Post-curing required with additional thermal treatment to acquire maximum heat deflection temperature of 238°C.

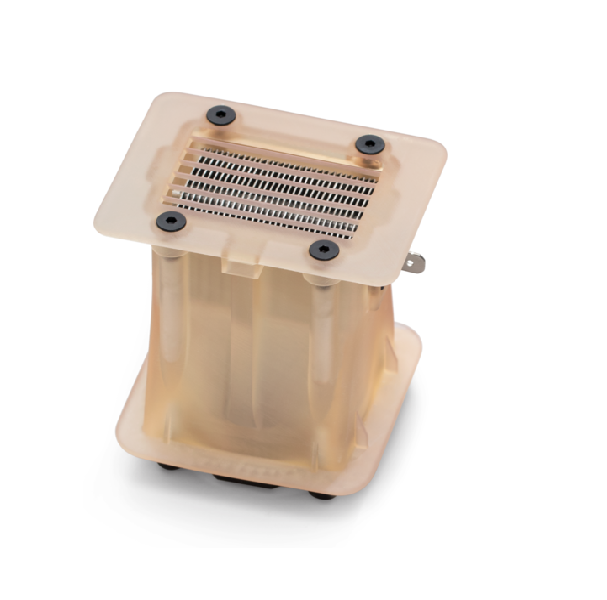

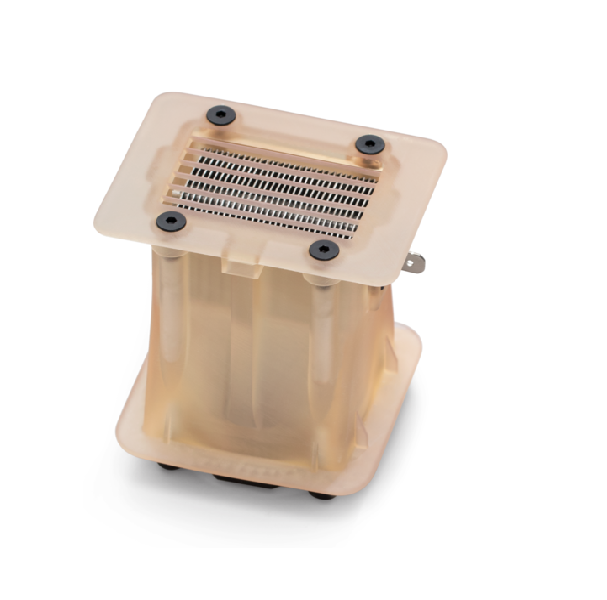

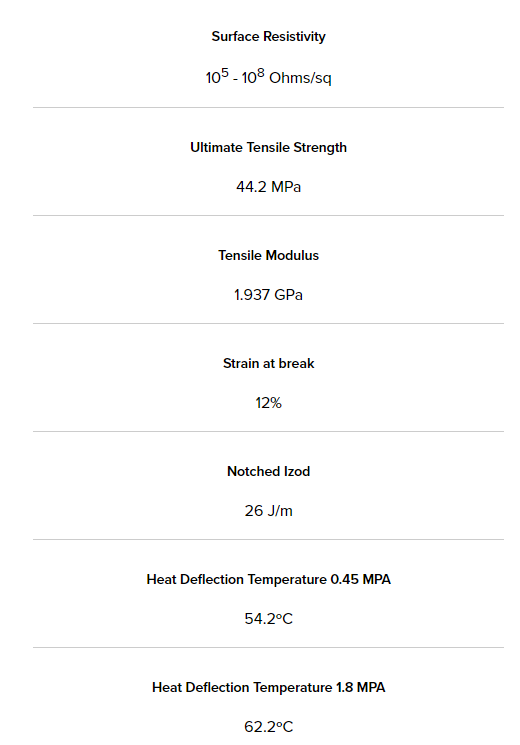

ESD

Reduce risk and increase manufacturing yield by 3D printing custom tools, jigs and fixtures with ESD Resin, protecting your critical electronics components from static discharge. ESD Resin is a cost-effective solution for producing static-dissipative parts designed to endure use on the factory floor.

Reduce risk and increase manufacturing yield by 3D printing custom tools, jigs and fixtures with ESD Resin, protecting your critical electronics components from static discharge. ESD Resin is a cost-effective solution for producing static-dissipative parts designed to endure use on the factory floor.

- Tooling & fixturing for electronics manufacturing

- Anti-static prototype and end-use components

- Custom trays for component handling and storage

Supports print resolutions: 100 and 50 microns. Post-curing required.

Printer compatibility: Form 3, Form 3+, Form 3L, Form 3B, Form 3B+.

Compatible with these resin tanks: Form 3/3B Resin Tank V2.1, Form 3L/3BL Resin Tank V1.

Compatible with these build platforms: Form 3 Build Platform, Form 3 Build Platform 2.

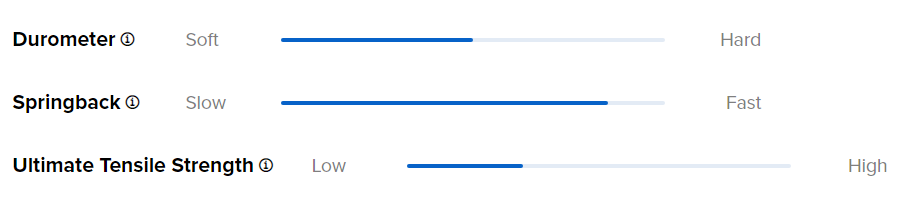

Elastic 50A

Our softest Engineering Resin, this 50A Shore durometer material is suitable for prototyping parts normally produced with silicone. Choose Elastic 50A Resin for parts that will bend, stretch, compress, and hold up to repeated cycles without tearing, and spring back quickly to their original shape.

Our softest Engineering Resin, this 50A Shore durometer material is suitable for prototyping parts normally produced with silicone. Choose Elastic 50A Resin for parts that will bend, stretch, compress, and hold up to repeated cycles without tearing, and spring back quickly to their original shape.

- Wearables, such as straps

- Stretchable enclosures and casings

- Compressible buttons

- Soft tissue anatomy

Supports print resolutions: 100 microns.

Post-curing required.

Requires Resin Tank V2 for Form 3 and Resin Tank LT for Form 2.

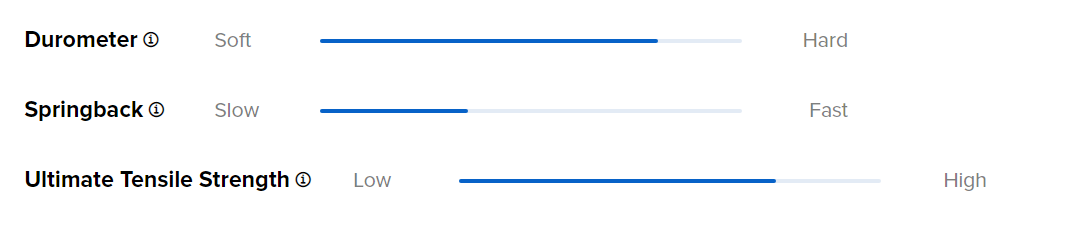

Flexible 80A

Flexible 80A Resin is the most stiff soft-touch material in our library of Flexible and Elastic Resins, with an 80A Shore durometer to simulate the flexibility of rubber or TPU. Balancing softness with strength, Flexible 80A Resin can withstand bending, flexing, and compression, even through repeated cycles.

- Handles, grips, and overmolds

- Cushioning, damping, and shock absorption

- Seals, gaskets, and masks

- Cartilage, tendon, and ligament anatomy

Supports print resolutions: 100 and 50 microns

Post-curing required.

Requires Resin Tank LT for Form 2.

Flame Retardant (FR)

Formlabs is proud to introduce Flame Retardant Resin, our first self-extinguishing and UL 94 V-0 certified material for stereolithography (SLA) 3D printing. Designed specifically for the transportation, aviation, manufacturing, electronics, medical and aerospace industries.

- Low-volume production parts for aerospace, aviation, automotive, and medical environments

- Tooling and manufacturing aids for high temperature environments or near ignition sources

- Electronics enclosures, connector housings and covers

- High-power electrical applications (e.g. transformer bobbins and relays)

Supports print resolutions: 100 and 50 microns

Post-curing required.

Printer compatibility: Form 3, Form 3+, Form 3L, Form 3B, Form 3B+, Form 3BL

Compatible with these build platforms: Form 3 Build Platform, Form 3 Build Platform 2, Form 3L Build Platform, Form 3L Build Platform 2

Resin Tanks

Formlabs Resin Tanks are consumables required for printing with any Formlabs 3D printer which wear over time depending of the material, part orientation and position, layer resolution and model size.

Each material should have it’s own Resin Tank to avoid decrease in print quality and damage to the device.

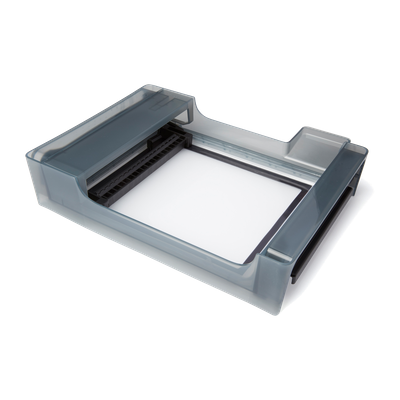

Form 3 Resin Tank

Low Force Stereolithography (LFS)™ 3D printing uses linear illumination and a flexible film tank to turn liquid resin into flawless parts.

Compatible with Form 3 and Form 3B.

Form 3L Resin Tank

Low Force Stereolithography (LFS)™ 3D printing uses linear illumination and a flexible film tank to turn liquid resin into flawless parts.

Compatible with Form 3L and Form 3BL.

Form 2 Resin Tank

The Resin Tank blocks light and is made from shatter-resistant polycarbonate. It comes with a reusable lid and wiper, making it easy to stack tanks and store resin outside of the Form 2.

Compatible with Form 2.

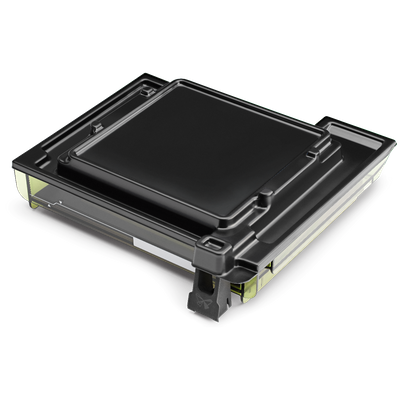

Form 2 Resin Tank LT

This tank was designed for printing in a high volume production environment and offers a longer tank lifetime than standard Form 2 Resin Tank for some Formlabs resins.

Compatible with Form 2.